Readers: If you want to build the project featured in today's post, please go to PCBWAY's Community pages--a gerber ready to download and/or fabricate as well as KiCAD files and a BOM are here.

Also please visit PCBWAY's site--using the link here--it will help this blog immensely. Thanks.

====

Last post I described a subcircuit that would take an audio signal from maybe 50K to below audible low frequencies and turn it into a square wave--useful for turning audio into a clock signal for an MPU.

It worked, but discussion ensued at my geeky audio meetup: is there an easier way to do this?

Of course there is....Elton at OtterMods had a similar circuit, with lower parts count, based on an LM311 comparator.

This post I'll discuss Elton's design, the LM311 comparator and build a prototype BreakOutBoard:

The Design:

How it works....

D1 turns a bipolar input at J1 into a signal at 0V and above.

That's fed into the inverting (-) input of the LM311.

The non-inverting (+) signal is the reference, with 12V for VCC, the 47K and 10K divider sets pin 2 at about 2V.

R5 sets the duration of the output signal.

The LM311 needs a pullup resistor (R7; 1K) while the 2N7000 FET and R6 inverts the output signal again.

LM311

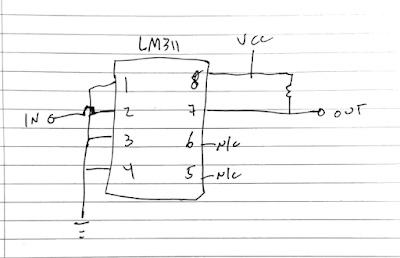

Which means: a pullup resistor at "collector Out", 3 to 15V at Vcc (pin 8), GND (pin 4) and a reference voltage (can be ground at presented at pin 3, the non-inverting input) is all you need; let the balance and bal/strb inputs float and tie EMIT OUT to GND.

So--we are talking 2 parts....the IC and one resistor to get a fully working, reliable, fast comparator.

Cool!

|

| 2 part comparator. For the pull up resistor: try 1K. |

More in the LM311 "benefits" column:

- Vcc to Vss can be 36V apart before you blow up the IC. Since we synth audio nerds often work with +/-12V or +/- 15V for our voltage rails: good fit.

- Simple operation--if the non-inverting voltage at pin 2 exceeds voltage at pin 3, the output (pin 7) goes from hi-z to low.

- Unlike an op amp, the 311's the inverting and non inverting-inputs are not virtual grounds--you can see the incoming signals on pins 2 and 3 with a DVM.

That turned out to be useful because when I first wired up Elton's design it didn't work due to an incorrect valued resistor. Throwing a DMM on Pin 2 helped me figure out my mistake.

THE BUILD

Elton emailed me his schematic and I laid out a small Breakout Board ("BoB") in Kicad.

I created a gerber, and off it went to this blog's patient sponsor, PCBWAY.

In a few days PCB's were back:

|

| Wham Bam, boards are back from PCBWAY. Please help out this blog and check 'em out. |

|

| Like the BoB in the previous post, I screwed up silks below the pin designations; pin numbers are wrong, and what pin is what? This is fixed in the version I uploaded to the PCBWAY community site. |

To make the BoB easier to breadboard I used 200mil edge connector pins; get your 100mil pin header male to male material and using needle nose pliers pull out every other solid wire.

It took me about 15 minutes to solder the parts to the board and connect the pin headers:

|

The IC went in then I dropped it on a breadboard to test.

And at output I got--nothing.

The output was slammed high, against the Vcc rail.

What?

This circuit is so simple, no way it could go wrong????

I probed the 311's pins, and Pin2 was 12V, not 2V. Hello?

No issues with soldering or traces.

After some fear and loathing: instead of a 47K/10K voltage divider, I errantly used a 470 ohm resistor for R3.

A 470 and 10K voltage divider is essential the same thing as the divider's source voltage.

DOH! Easily fixed--put in the right value resistor!!

|

| "One of these things is not like the other" |

|

| With the correct part values: "seems working" |

Elton's design worked great, nice clean square waves regardless of a sloppy signal at the LM311's inverting input.

Low parts count--and, if I went with an SOIC LM311 and SMD resistors, this design could get really small.

So what next? I hope to use this BoB for input buffering and rising edge detection for a clock multiplier, perhaps based on an RP2040.

But! With my day job going full swing post-pandemic, will I have time? We will see.