Why = Whynot?

So let's build a Vactrol envelope follower I initially drew up when dinosaurs still roamed the earth:

|

| A Poor Lazertran decal application detracts from the finished prototype--don't know what I was thinking with the bun n' weiner vertical graphic on the left side of the module. The front panel will have to redone. |

|

| For the 2019 PCB, there is a serious trace issue with the + and - rails feeding the quad op amp. Doh! I had to cut traces and add kludge wires. This will be fixed in a newer version of the PCB. |

What the VAC: In 2004 I had even less idea what I was doing then I do now, but I think the module came out OK; you can hear a sound clip of the module here. Pretty much everything you hear is processed in some way through this module, to create auto-wah, side chain effects, amplitudes creating modulation via CV on a VST via an Expert Sleepers interface, and so on.

USING THE VAC-Envelope Follower:

The VAC-EF uses amplitude seen at input to generate a corresponding DC voltage at its output. If you've ever experimented with an auto-wah device such as a Mutron III or an optically based compressor/limiter you've used amplitude to voltage conversion circuits, a bit like this one, before.

Here's a typical application: change a bandpass filter's center frequency in response to the amplitude of an audio signal. Sounds like Jerry, right? Also: side chain effects: a drum track gets louder when another track is soft, for instance. Or: change phase when there is a loud passage for phase shifty sounds, crank up a distortion effect when the instrument you want to mangle is really loud, but not so much when it's soft, or for any of this, do the opposite.

Here's a typical application: change a bandpass filter's center frequency in response to the amplitude of an audio signal. Sounds like Jerry, right? Also: side chain effects: a drum track gets louder when another track is soft, for instance. Or: change phase when there is a loud passage for phase shifty sounds, crank up a distortion effect when the instrument you want to mangle is really loud, but not so much when it's soft, or for any of this, do the opposite.

BUILDING the VAC-EF:

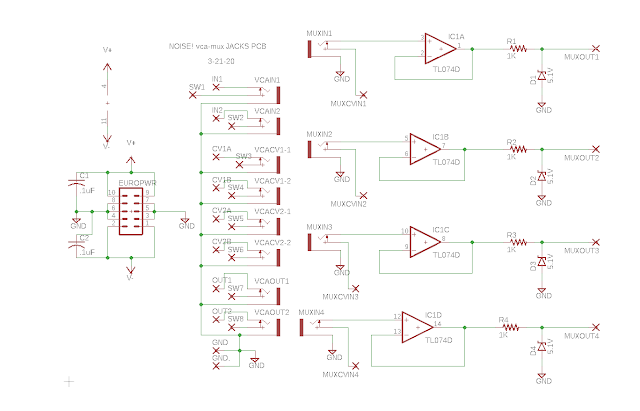

Here's the schematic from 2019:

|

| I used audio taper pots for Sensitivity and Slope. R16 "Bias" pot is linear taper. |

Board is designed to fit behind a 1u Frac panel:

|

|

| Temp Front Panel!!! Does it surpass the weiner? |

Overall the vactrol gives the module a slow, drunken, sloppy feel, which to my ears is (sometimes) a good thing.

But Why, Scotty, Why: I am not sure if the current source (a simple 7805L regulator) for the Vactrol is a smart design choice, but it works, I used this junk box part to supply current to the opto because I have a lot of 7805's in my junk box. How about putting the 2222 transistor in the feedback loop of the op amp ICB1? Is this a good idea? Not sure--I am not even sure it's necessary, but regardless, I was experimenting and boosting the current in this matter gave the output a bit more "kick" so I kept this fragment in the design.

Overall, I've used this module for the past 15 years and have been happy with its performance. The TL084 gets a bit hot sometimes depending on the module's settings which means the design could be improved; I'm not sure why it gets hot, but I'm too busy with other projects to fix it.

If you do build one of these, mess with R5 value to set the overall performance of the circuit. You might even consider putting a trimmer in series with R5.

Here are some bench photos:

My initial test PCB used normal 9mm PCB pots and small knobs but as you can see the ergonomics were unacceptable. Hence I replaced them with tall trimmers which you can buy from Thonk:

FIXES: Again: if you build this module, it's important to note that what I have posted on my website has some mistakes in the layout. Specifically, I had to add 2 kludge wires since I screwed up the wiring for V+ and V- rails for the quad op amp.

The Eagle files, PDFs including the fixes, etc. etc. are on my website, here.

For the 2020 board revision: I still need to test it further. May do a dual VAC-Envelope follower in a 2u Frac? A quad SMD version? A version with 4 EF's, each with its own active bandpass filter? Who knows.

Until then, have fun VAC-uuming, always suck at everything while you can, and above all (especially now right? Stereo Pan-demic!) don't breathe the fumes!