rubbish, let's go retro. I always liked those little LED bubble displays growing up so how about those?

That means: current sourced to A1-A8 light up segments of the LEDs in a single bubble, which are laid out like this:

OK with that super basic knowledge under my belt, it was time to see if anyone had already written up an easy way to hook 7 segment displays up to Arduino type MPUs. Why reinvent the wheel?

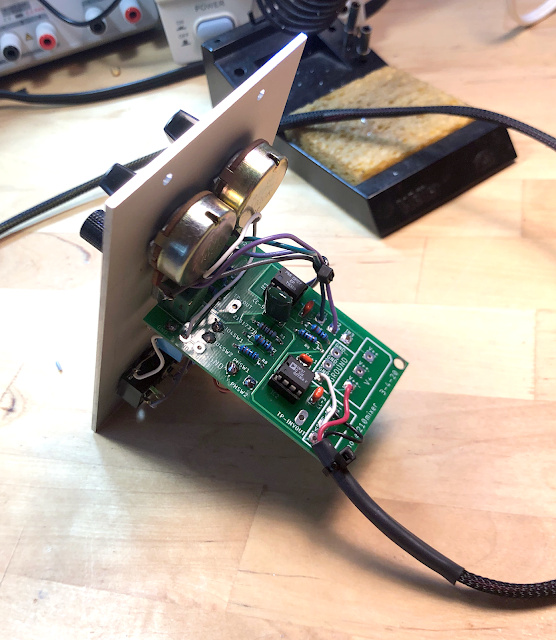

OK, let's motorize this pursuit.....

OK how about the code? Here is what I was using to get the pot to go--I wrote other variations to try out other things, comment if anyone wants to see those.

This wasn't too hard--it took a couple of evenings. I got stuck for maybe an hour on one strange thing--the bubbles wouldn't work reliably if I was using Serial.write to debug. Commenting the serial stuff out, the bubbles worked again. So I was introducing a bug by debugging? A pest, but yes.

A few >'s instead needed to be <' s but overall, not bad at all.

//////////******************************

long testnumber = 0;

//testnumber is what I want to show up on the NSA1166.

//you have to use long. int only goes to 32000 or something close!

//////////******************************

unsigned long startMillis; //start millis timer

unsigned long currentMillis;

const unsigned long period = 10;

//each item in the array below ground a given pin of a 595, so the Bubble can display.

int mybubble[] = {124,188,220,236,244,248};

int c = 0; /* used to hold number of elements in the array */

long n;

int p = 0; // counter for filling array with elements.

int numberArray[6];

//this holds each value of number we are trying to display

// bubble zero is leftmost bubble!

long bubble5 = 0;

long bubble4 = 0;

long bubble3 = 0;

long bubble2 = 0;

long bubble1 = 0;

long bubble0 = 0;

//pins used to feed shift regs

//Pin connected to ST_CP of 74HC595

int latchPin = 8;

//Pin connected to SH_CP of 74HC595

int clockPin = 12;

////Pin connected to DS of 74HC595

int dataPin = 11;

//pot wiper connected to A0. gnd AND 5V for the rest

int pot = A0;

void setup() {

// put your setup code here, to run once:

//set pins to output so you can control the shift register

pinMode(latchPin, OUTPUT);

pinMode(clockPin, OUTPUT);

pinMode(dataPin, OUTPUT);

// debug using serial

//Serial.begin(9600);

// BE CAREFUL serial stuff can step on Bubble display and make it mysteriously not work.

// initialize array

numberArray[0] = 0;

numberArray[1] = 0;

numberArray[2] = 0;

numberArray[3] = 0;

numberArray[4] = 0;

numberArray[5] = 0;

}

void loop()

{

//do a analog read every 10ms

currentMillis = millis();

if (currentMillis - startMillis >= period) //test whether the period has elapsed

{

testnumber = analogRead(pot);

startMillis = currentMillis;

}

c = 0;

// turn that number into an array. Note: ARRAY is backwards!

//first we need to determine how many digits the number in ques\ton has. We need that to send //blanks out later

n = testnumber;

while (n != 0)

{

n /= 10;

c++;

}

/* Serial.println("testnumber variable value is: ");

Serial.println(testnumber);

Serial.println("length of array is: ");

Serial.println(c);

*/

/////////////////

n = testnumber;

p = 5;

//now fill an array with each digit.

while ((p > -1) && (n != 0))

{

numberArray[p] = n % 10;

n /= 10;

/*

Serial.print("----------");

Serial.println("We are seeing output of array value");

Serial.println(p);

Serial.println(numberArray[p]);

Serial.println("");

*/

p--;

}

//wanted to time more CRAP then realized it wasn't needed, comment that!

//Leaving it here in case I remember what I was thinking.

////currentMillis = millis();

//if (currentMillis - startMillis >= period) //test whether the period has elapsed

//{

//startMillis = currentMillis; //update current millis.

/////////////////////////////////////////////////

//YEH next part can be simplified and made into a single function.

//I am too lazy to do this. you do it!

//AND--I don't accommodate decimal points at all.

//Again I am too lazy.....

////////////////////////////////////////////

bubble5 = getbyte(numberArray[5]);

//write to shift reg. rightmost digit.

// take the latchPin low so

// the LEDs don't change while you're sending in bits:

digitalWrite(latchPin, LOW);

// next line puts numeric data onto shift register

shiftOut(dataPin, clockPin, LSBFIRST, bubble5);

// then pick which bubble to impact

shiftOut(dataPin, clockPin, LSBFIRST, mybubble[5]);

//take the latch pin high so the LEDs will light up:

digitalWrite(latchPin, HIGH);

//write to shift reg digit. 2nd from right

if (c < 2)

{

bubble4 = 0;

}

else

{

bubble4 = getbyte(numberArray[4]);

}

// take the latchPin low so

// the LEDs don't change while you're sending in bits:

digitalWrite(latchPin, LOW);

// next line puts numeric data onto shift register

shiftOut(dataPin, clockPin, LSBFIRST, bubble4);

// then pick which bubble to impact

shiftOut(dataPin, clockPin, LSBFIRST, mybubble[4]);

//take the latch pin high so the LEDs will light up:

digitalWrite(latchPin, HIGH);

//write to shift reg digit. 3rd from right

if (c < 3)

{

bubble3 = 0;

}

else

{

bubble3 = getbyte(numberArray[3]);

}

// take the latchPin low so

// the LEDs don't change while you're sending in bits:

digitalWrite(latchPin, LOW);

// next line puts numeric data onto shift register

shiftOut(dataPin, clockPin, LSBFIRST, bubble3);

// then pick which bubble to impact

shiftOut(dataPin, clockPin, LSBFIRST, mybubble[3]);

//take the latch pin high so the LEDs will light up:

digitalWrite(latchPin, HIGH);

//write to shift reg digit. 4th from right

if (c < 4)

{

bubble2 = 0;

}

else

{

bubble2 = getbyte(numberArray[2]);

}

// take the latchPin low so

// the LEDs don't change while you're sending in bits:

digitalWrite(latchPin, LOW);

// next line puts numeric data onto shift register

shiftOut(dataPin, clockPin, LSBFIRST, bubble2);

// then pick which bubble to impact

shiftOut(dataPin, clockPin, LSBFIRST, mybubble[2]);

//take the latch pin high so the LEDs will light up:

digitalWrite(latchPin, HIGH);

//write to shift reg digit. 5th from right

if (c < 5)

{

bubble1 = 0;

}

else

{

bubble1 = getbyte(numberArray[1]);

}

// take the latchPin low so

// the LEDs don't change while you're sending in bits:

digitalWrite(latchPin, LOW);

// next line puts numeric data onto shift register

shiftOut(dataPin, clockPin, LSBFIRST, bubble1);

// then pick which bubble to impact

shiftOut(dataPin, clockPin, LSBFIRST, mybubble[1]);

//take the latch pin high so the LEDs will light up:

digitalWrite(latchPin, HIGH);

//write to shift reg digit. leftmost

if (c < 6)

{

bubble0 = 0;

}

else

{

bubble0 = getbyte(numberArray[0]);

}

// take the latchPin low so

// the LEDs don't change while you're sending in bits:

digitalWrite(latchPin, LOW);

// next line puts numeric data onto shift register

shiftOut(dataPin, clockPin, LSBFIRST, bubble0);

// then pick which bubble to impact

shiftOut(dataPin, clockPin, LSBFIRST, mybubble[0]);

//take the latch pin high so the LEDs will light up:

digitalWrite(latchPin, HIGH);

} // end main loop

//shiftOUT does not seem to accommodate bxxxxxxx typle format?

//whatever, I am using decimal values for this.

byte getbyte(long x)

{

int a;

if (x == 0)

{

a = 252; //11111100

return a;

}

if (x == 1)

{

a = 96; //011000000

return a;

}

if (x == 2)

{

a = 218; //11011010

return a;

}

if (x == 3)

{

a = 242; //11110010

return a;

}

if (x == 4)

{

a = 102; //01100110

return a;

}

if (x == 5)

{

a = 182; //10110110

return a;

}

if (x == 6)

{

a = 190 ; //10111110

return a;

}

if (x == 7)

{

a = 224; //11100000

return a;

}

if (x == 8)

{

a = 254 ; //11111110

return a;

}

if (x == 9)

{

a = 230 ; //11100110

return a;

}

}

Also, would be nice to get decimals going, but I don't have an immediate need for that, so for now, wah-wah.

That's it, no smoke, no fumes, bubble up the covid and leave it behind!