Welcome back to the land of.....

I started this Lunetta build maybe 18 months ago.....

Finally done:

BLAH BLAH! JUST LINK THE SOUND SAMPLE!

if you want to hear the finished Lunetta synth, in action, soundcloud sound clip is here.

Boy Howdy! this started with a board swap with Reverselandfill.org (there is a newer version of Reverselandfill's NOISE! module, V8, here). The NOISE! Osc is a CMOS based chaotic sound generator, and right out of the box is a very cool build....

|

| V6 of Noise!--older design, now it's up to V8 |

I built the original "stock" NOISE! module something like 16 months ago--it's a finished module--orig post is here:

But can never leave anything alone, so after discussing with Martijn, I created a not-for-sale PCB based on his original design, but sized to fit a smaller (non Frac) enclosure. Following that was a quad digital pot board controlled by Arduino (post here), a 4051 based mux board (again Arduinoized, post here), and a dual VCA board (post here). I even used 3D printing to create hardware to mount the "stacks" (here)--3D printing was totally new for me.

All that was left to finish this off was to create a power supply and a PCB to have blinky LEDS and to things power on--since there was leftover space on this latter PCB, I threw a 555 VCO on there. Why not?

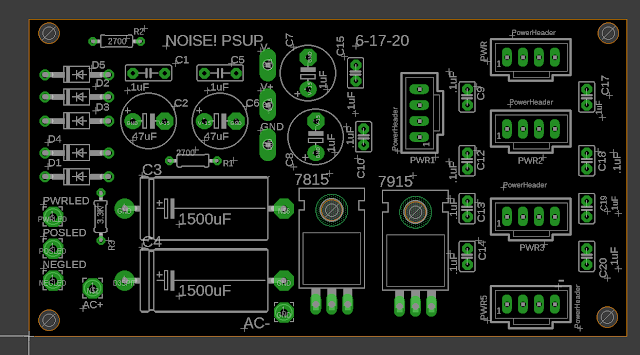

Here's the psup, based on the usual PAIA linear design you find in fracs.

PSUP was quickly off to china for PCB fab; back, built.

The first Psup built kept blowing up (I mean BANG!!! and smoke, total destruction) the diodes used for rectification. I pretty much sucked every part off the board looking for the short but never found it, so I built another. Of course: Second one, almost all the same parts, same everything, worked.

|

| Wow--That Diode Blew up Real Good! |

|

| Why did the 2nd one work? No, not the missing reg. It was something else. |

OK with the power supply temporarily not exploding, I next found that all the stacks combined drew about 150mA on the + rail and about 30mA on the - side. There were at least 2 instances of the + rail being dropped to 8V or 5V for the Arduinos. This meant that the 7815 regulator I was using got very, very hot, even with a decent sized heatsink attached.

I didn't want the damn lunchbox thing to melt, so, what to do?

At digikey I found this part:

I figure this part was designed for engineering amateurs and general bozos like me, who design linear power supplies and ignore any sort of heat loading. Very nice!

It's almost a magic part: a switching regulator that's a direct drop in for a linear regulator--with 92% efficiency, something like that? so no heat! and after putting that in (it was a direct replacement size wise for the 7815) the heat problem was gone.

New problem though--powering everything on, the + rail would sometimes refuse to come online. After a few power ons and offs, it would come up. Strange!

Probably some filter cap issue downstream, but, whatever; I never figured this out, but just flicking the master power switch off and on a few times before using the lunchbox in the studio didn't seem like a big deal; I thought of it as an old motorcycle that doesn't always start the first time, right?

Last thing to build was a "jacks board" to hold things like the power switches, power rail LEDS and so on--since I had some space I threw a 555 VCO on there, but it could have been anything, here it is waiting to be mounted to the power supply.

|

| "Every Project needs a 555" |

I then got out the Antique rocket ship/jr. scifi lunchbox I bought on Ebay a few months ago--perfect graphics and patina for a Lunetta synth right?

OK, I dropped in all the boards etc. Good news: The 3D printing came out OK, it provided a tight enough fit that I didn't need to cut up the lunchbox to screw anything in, it's all just a press fit in there, and so far seems to be good enough.

Last thing to do is get it in the studio and make sure it all works. It does! Joy! No smoke! No Fire! Bizarre sounds!

The synth is odd craziness as you suspect, but overall I think it's mostly good for atonal beep-beep-beep non repeating sort of stuff. Think of an alarm clock you seriously want to throw off a cliff?

On the demo it's about 80% audio out from the lunchbox, but I also have the lunchbox providing chaotic CV to things like a Rings module. Like the original NOISE! it seems good for both audio and CV.

As far as posting allo the schemos etc etc--well, there is a ton of PDFs, eagle files etc etc., I will just make a giant ZIP of all of it and post it soon. UPDATE: 8-22-20. Eagle files and other "as built" docs are now posted. Go to my website here. I will try to add scan and add PDFs down the road.

Many thanks and big shout out to Martijn Verhallen of reverselandfill--thanks for the support and encouragement.

Wow--can't believe it's done.

Enuf! There are bad fires right now in not so sunny California, so there are even more fumes to not breathe--don't breathe 'em. Hold your breath.