Back in analog-land: time to replace a Frac bench panel with something more high class.

|

| Panel on the left passively converts 3.5mm jacks to 22-ish gauge binding posts connected to a power amp. Top notch aethetics, right? |

The old board, built from a frac aluminum panel, worked, but was butt-ugly.

Let's redo this in Euro!

I figured I might as well throw in a mixer while I'm at it.

Easy right? This is a couple of non-inverting op amp mixers. I can lay this out in my sleep! It will work first time!

Nope.

Bing, bam, boom! Designed in Eagle....created gerbers....got the boards back pronto from this blog's patient and highly enthusiastic sponsor, PCBWAY:

|

| Happiness is new boards from PCBWAY! Please help this blog and check 'em out. |

The project was centered around dual contentric pots (you can get these from small bear and other DIY vendors), but I could only find these in 90 degree variations, not 180 degrees. So, not a slam dunk for Euro skiff, which has to not exceed about 30mm in depth.

I might try to lay out a skiff-friendly adapter for these handy dual concentric pots, but this time I ended up side-mounting the PCB:

|

| Why is it not fully soldered? D'oh! Keep reading.... |

|

| (HONK!) For volume to go up when you turn the knob up, the arrows have to go up! |

|

| Nice kludge wire for ground |

Also the L1, R1, L2, R2 wires from jacks to main board were out of order. I tried cutting and rewiring the 4 conductor jumper but about halfway through I realized: too many stoopid mistackes, too many kludges, shut up n' redesign the damn PCBs.

|

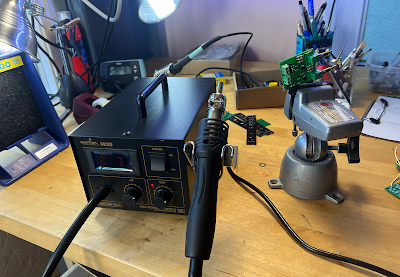

| The grim reaper of DiWHY?--sparkfun air work station |

|

| Improved jacks board with a ground! |

No comments:

Post a Comment